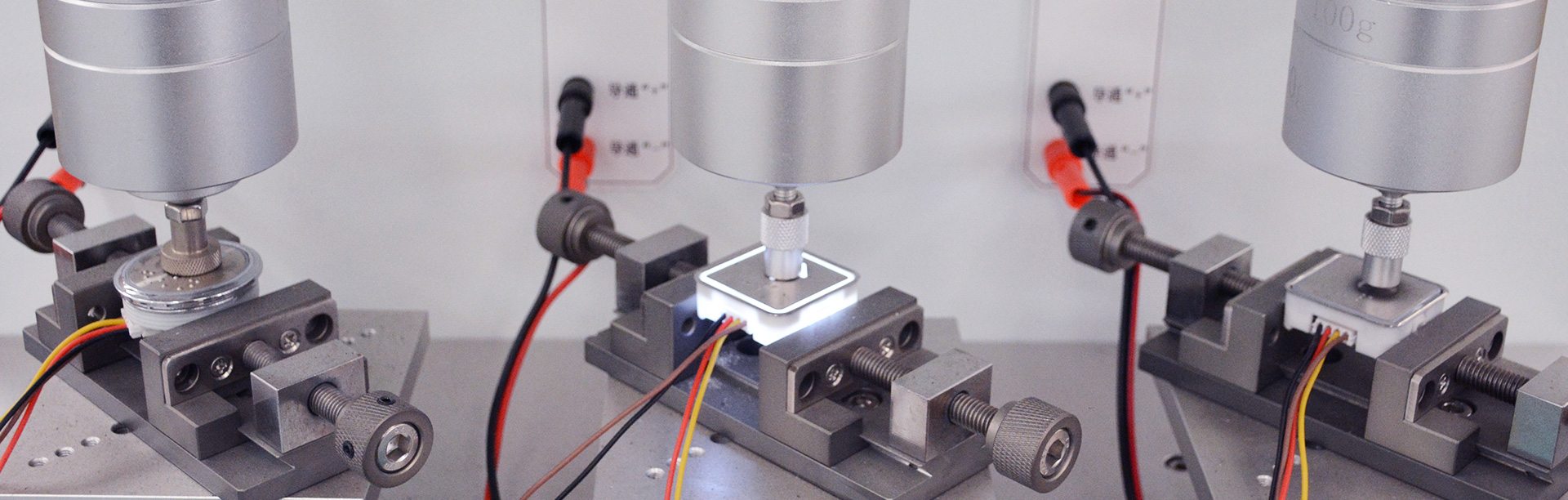

Izisetshenziswa:Umshini wokuhlola impilo yonke yenkinobho ye-elevator

Inkinobho Isikhathi Sokuphila (izikhathi eziyisigidi):T/CEA 0012—2020 >3, ilifti ye-Koyo >6

Izimo zokuhlola:Ukuhlola kwenziwa ekamelweni lokushisa, futhi inkinobho ifakwe endaweni yesikhulumi esingashintshi.Vula umshini, futhi inkinobho iyakhanyiswa.

Imvamisa:Hz ngaphansi kuka-1Hz;ingcindezi: hhayi ngaphansi kuka-10N.

Umbandela:Umsebenzi ojwayelekile, ukusebenza kahle kukagesi;Izinga lokuhluleka alikho ngaphezu kwezingxenye ezi-2 ngesigidi ngasinye.

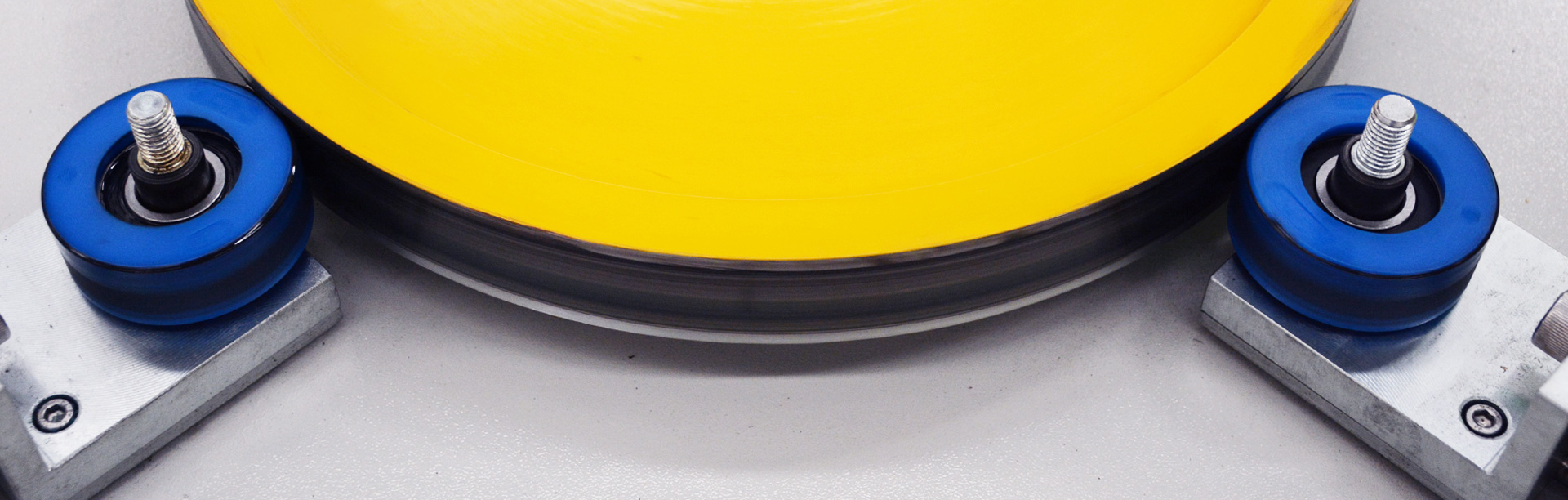

Izisetshenziswa:Izitebhisi ezizihambelayo (i-pedal) ibhentshi lokuhlola ukuthembeka kwe-roller

Isikhathi sempilo yerola:I-TSG T 7007-2016: ingcindezi enkulu yokulayisha i-roller kanye nesikhathi sokugijima sokuhlola okungenani yi-1300N, 250h

Izimo zokuhlola:Ukuhlolwa kwenziwa ekamelweni lokushisa, futhi kufanele kuhlolwe emshinini okhethekile wokuhlola ukukhathala kwe-roller.I-roller kufanele ifakwe endaweni yesikhulumi esinqunyiwe, futhi i-roller kufanele ifakwe ngokuqinile futhi ifakwe ngokulinganayo.Ukuzungezisa Bushelelezi.

Indlela yokuhlola:Ohlotsheni ngalunye lokucaciswa kwe-roller,amarola amane njengesethi eyodwa.kufanelekile ukwandisa inani lamaqembu okuhlola;Ukucindezela kokulayisha kufanele kusethwe ngokuhambisana nesikhathi sokuhlolwa (bona incazelo yesikhathi sokuphila kweRola).

Umbandela:Izohlangabezana nezidingo ezicaciswe yiyunithi yokukhiqiza (isivinini somugqa wokuhlola, ingcindezi yokulayisha, isikhathi sokugijima sokuhlola), futhi irola ngeke libe ne-concave yendawo kanye ne-convex, i-degumming, ukuqhekeka nezinye izenzakalo ngemva kokuhlolwa.

Impilo ye-Brake (izikhathi eziyisigidi):GB/T24478-2009 >2, ilifti ye-Koyo >4

Izimo zokuhlola:Ukuhlolwa kwenziwa ekamelweni lokushisa.Ibhuleki lifakwe emsamo womshini wokudonsa, ibhuleki livulwa ngokushintshwa kwamandla, bese kuvulwa ibhuleki bese liyadedelwa.

Indlela yokuhlola:Isikhathi sokuphendula sesenzo samabhuleki akufanele sibe sikhulu kuno-0.5s, umjikelezo wokuhlola awukho ngaphansi kwama-5s aqhubekayo wokuhlolwa kwesenzo esingaphazanyiswa.

Umbandela:Umsebenzi ojwayelekile, ukusebenza kahle kukagesi;Akukho ukulungiswa okufanele kwenziwe ngesikhathi sokuhlolwa, futhi ukusebenza ekupheleni kokuhlolwa kusafanele kuhlangabezane nezidingo ezifanele ze-“GB/T24478-2009 elevator trekta” 4.2.2.2 kanye no-4.2.2.3.

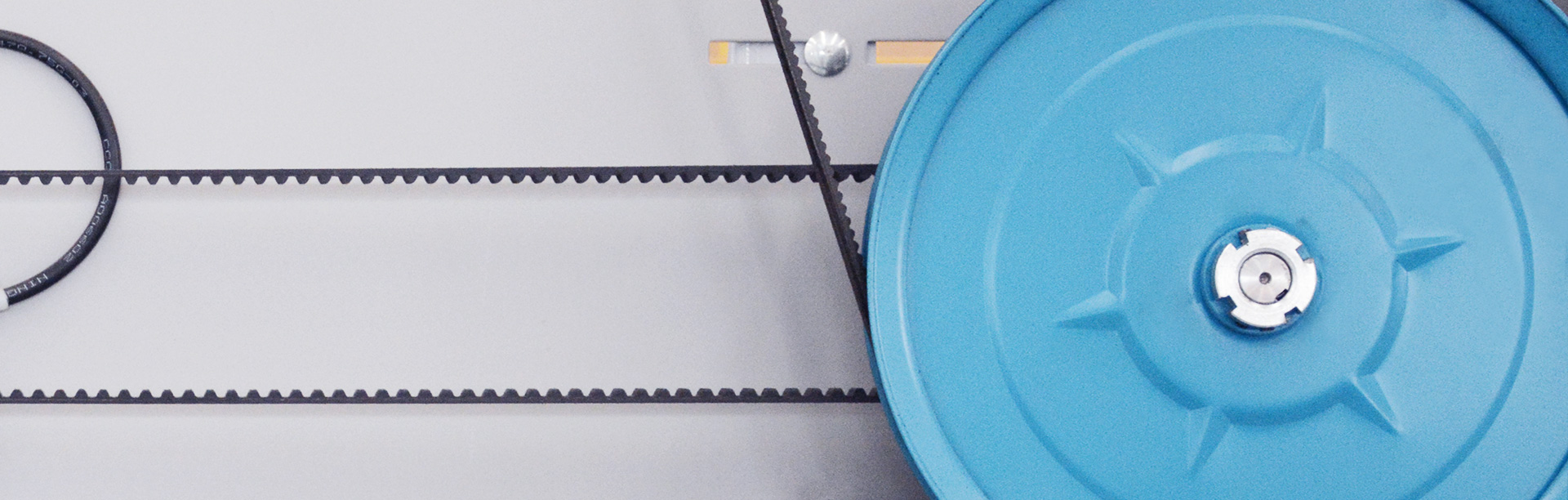

Izisetshenziswa:Umqhubi womnyango & ukulinganisa komnyango wemoto ogijima umshini wokuhlola.

I-KOYO Elevator ejwayelekile:izikhathi ezingaphezu kwezigidi ezingu-6.

Izimo zokuhlola:Ukuhlolwa kwenziwa ekamelweni lokushisa.I-opharetha yomnyango kanye nomnyango wemoto ifakwe endaweni engaguquki, bese ivula i-opharetha yomnyango.

Indlela yokuhlola:Uhlelo lomnyango kufanele lusebenze ngesivinini esingama-240 izikhathi ngehora.

Umbandela:Alikho iphutha, umsebenzi ojwayelekile, ukusebenza kahle kukagesi;Ukugqokwa kwentambo yocingo, i-pulley yomhlahlandlela wezintambo, ibhande lomqhubi womnyango, ikhebula elihambisanayo nezicathulo zomnyango wokumisa zihlangabezana nezidingo zokuklama.